Innovative Home Fiber Fiber Cable Production Line Gear Packages

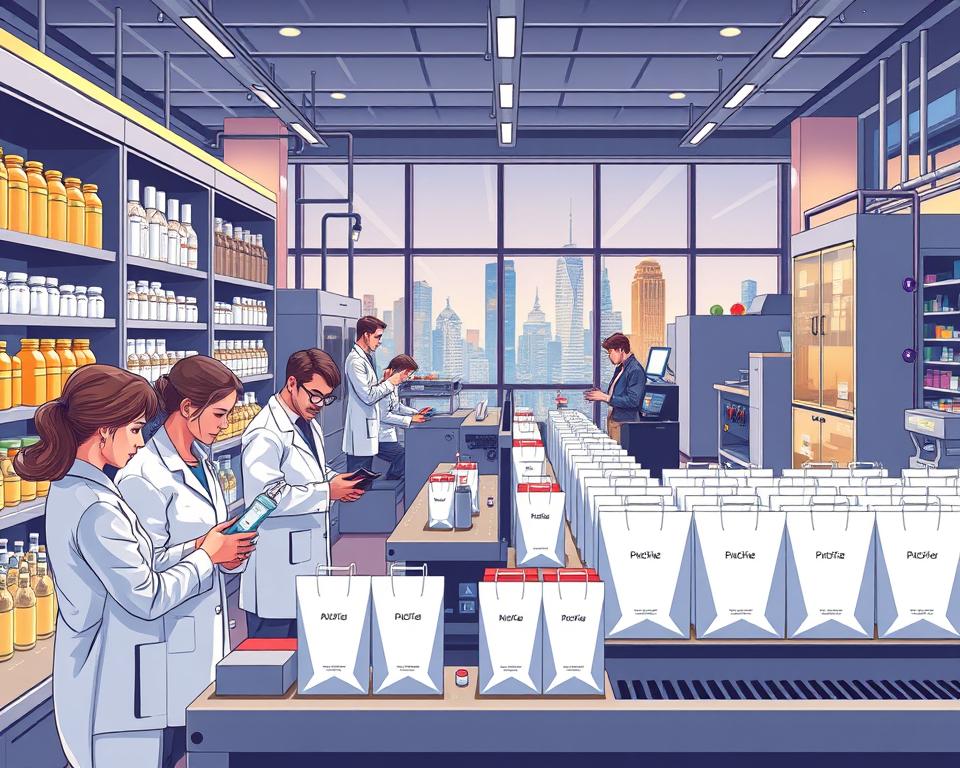

Ever pondered the impact of rapidly growing internet cable demand on FTTH cable production technology? With our need for high-speed, reliable connectivity rising, manufacturers like HONG KAI and Nextrom are transforming production. They are introducing innovative cable equipment to improve production efficiency. Not only does this shift slash operational costs but also enhances high-speed internet cable quality, satisfying today’s market standards.

Here, we’ll explore the game-changing equipment and methods redefining Fiber coloring machine manufacturing. Discover how these innovations are ready to reshape the fiber optic sector.

Essential Insights

- Grasping the importance of FTTH cable production line equipment in high-speed internet access.

- Exploring the significant role of companies like HONG KAI and Nextrom in driving technology innovation.

- Discovering the benefits of adopting advanced cable equipment in manufacturing processes.

- Identifying how improved cable quality is essential for meeting consumer demands.

- Appreciating the importance of production efficiency in a competitive market.

Grasping FTTH Cable Production Line Technology

The creation of fiber optic cables, primarily for FTTH technology, involves a complex blend of state-of-the-art tools and precise methods. Modern production of these cables includes various components that improve efficiency and quality. Knowing these parts illuminates the progress toward more advanced production systems.

Core Components of Modern Fiber Optic Cable Manufacturing

Current fiber optic cable production includes:

- Extrusion systems for coating and insulating fibers

- Fiber tension control mechanisms to maintain optimal fiber quality

- Automated operations that simplify production processes

These elements work together to produce a dependable and long-lasting product. For instance, state-of-the-art temperature control systems ensure consistent conditions. Automated adjustments also minimize human error.

Evolution from Traditional to Modern Production Systems

The shift from traditional to automated systems represents a significant leap in technology and methods. Older, manual methods have been superseded by automated systems. This transition has resulted in:

- Higher productivity and reduced production times

- Reduced waste due to precise material handling

- Improved product quality thanks to stricter quality control

Key Technologies Driving Industry Innovation

Several core technologies are driving innovation in the fiber optic field. These include:

- Precision temperature control that monitors and maintains optimal production conditions

- Automatic settings that adapt to changing production requirements

- Advanced monitoring systems offering real-time feedback on production quality

Thanks to these technologies, manufacturers can ensure their fiber optic products meet the stringent standards required for FTTH applications.

Essential Equipment for Fiber Secondary Coating Line Operations

In the realm of fiber optic cable manufacturing, the fiber secondary coating line is crucial. It safeguards fiber optics through high-speed coating processes. With technology advancing, equipping with the latest equipment is vital for optimal production and reliability.

High-Speed Secondary Coating Processes

Advances in secondary coating processes have significantly improved manufacturing efficiency. Modern systems can now handle increased volumes, addressing rising demand. They apply coatings that boost durability and performance, resulting in superior fiber cable products.

Single and Dual Layer Coating Applications

It’s important to know between single and dual layer coatings in the fiber secondary coating line. Single-layer coatings offer basic protection, while dual-layer coatings add extra resistance to environmental stressors. Both methods employ high-speed processes for even coating application, ensuring fiber optics perform longer in various conditions.

Temperature Control and Curing Systems

Temperature control systems are vital for curing coatings during production. They maintain the right conditions for adhesive substances in the fiber secondary coating line. Proper temperature management allows for perfect curing times and conditions, resulting in higher quality fibers ready for real-world use.

Fiber Draw Tower and Optical Preform Processing

The fiber draw tower is central in optical preform processing and cable manufacturing. It draws the preform into thin fiber strands, guaranteeing high-quality fibers with exceptional clarity and strength. The tower’s environment is carefully controlled to achieve precise dimensions and physical properties.

Optical preforms are the foundation of this process, defining the fiber’s final characteristics. The preform’s quality affects light transmission and durability. Advances in preform manufacturing have boosted fiber ribbon line manufacturing efficiency.

Through advanced engineering and technology, the fiber draw tower and preform processing constantly evolve, meeting the growing demand for high-performance fiber optic cables. Quality at the preform level yields better fiber optics, enhancing telecommunications and networking services.

Advanced SZ Stranding Line Technology for Cable Assembly

The SZ stranding line technology marks a major advancement in cable assembly, especially for fiber optic cables. It provides precise stranding, vital for crafting top-tier cables that adhere to strict standards.

Precision Stranding Equipment Features

The core of the SZ stranding line is its precision stranding equipment, which enhances cable durability and reliability. Its key attributes include:

- Sophisticated control systems that fine-tune settings in real-time for peak performance.

- High-speed operation that boosts production efficiency.

- Modular design for customization based on production needs.

Automated Tension Control Systems

Automated tension control systems are critical for maintaining consistency in stranding. They:

- Ensure uniform fiber tension and strength distribution along the cable.

- Lower defect rates, cutting down on waste and production costs.

- Allow seamless integration of diverse materials, improving flexibility and performance.

Integration with Fiber Cable Sheathing Line

The integration of the SZ stranding line with the fiber cable sheathing line elevates production efficiency. This synergy enables for:

- Streamlined workflows by minimizing manual intervention.

- Consistent quality throughout the manufacturing process.

- Increased throughput, meeting the growing need for superior cables.

Fiber Coloring Machine and Identification Systems

The fiber coloring machine is vital in telecom fiber cable production. It guarantees each cable is identifiable and complies with color coding standards. Advanced technology enables quick and accurate color application, boosting manufacturing efficiency.

High-Speed Coloring Technology

Cutting-edge machines use high-speed technology for consistent and fast color application. This reduces production time without compromising quality. The machines’ precision ensures accurate color application, aiding adherence to strict color coding standards, essential for smooth installation and maintenance.

Color Coding Standards for Telecom Fiber Cables

Color coding standards guide manufacturers and technicians in the telecom industry. They systematize fibers for easy identification, minimizing installation and troubleshooting errors. Each color denotes a specific function or fiber type, guaranteeing clarity in complex networks.

Following these standards, enabled by fiber coloring machines, improves safety and efficiency—a cornerstone of telecom operations.

Quality Control in Fiber Identification

Quality control is critical in fiber identification systems to meet market standards. Routine inspections during production verify color accuracy and coding adherence. Advanced traceability systems trace fibers, boosting product reliability.

This methodical quality control approach produces superior telecom fiber cable performance, satisfying both manufacturers and end users.

Specialized Solutions for Fibers in Metal Tube Production

The production of fibers in metal tubes is a key domain in modern cable solutions. This method enhances durability and environmental resistance of optical cables, rendering them ideal for harsh conditions. Specialized techniques encase fibers in metal, shielding them from damage and extreme environments.

In outdoor settings, where cables face tough elements, these solutions prove their worth. Manufacturers have engineered advanced methods to fortify and boost cable reliability, meeting the growing demand for durable communication systems. Precision SZ stranding line engineering and premium materials are essential in this process.

Employing specialized manufacturing methods guarantees cables remain intact and functional across industries. Companies focus on innovative designs and robust materials to create top-tier optical cables for diverse environments and applications.

Fiber Ribbon Line and Compact Fiber Unit Manufacturing

The manufacture of fiber ribbons and compact fiber units is critical for modern telecommunication networks. This section highlights the latest equipment and designs for these essential components. Innovators aim to meet the rising demand for high-density cable solutions in data centers.

Advanced Fiber Ribbon Line Equipment

State-of-the-art fiber ribbon line equipment allows efficient production of high-quality optical fibers. It integrates the latest technology to produce compact fiber units with top performance, reducing waste and improving throughput to suit various needs.

Compact Fiber Unit Design and Production

Compact fiber units are designed for space efficiency without sacrificing performance. Innovative methods shape these units for easy installation in diverse settings. These units are key for data centers, addressing the need for dense cables that save space and accelerate data transfer.

High-Density Cable Solutions for Data Centers

High-density cable solutions are critical for modern data centers, enabling faster data transfer and greater bandwidth. These solutions often incorporate fiber ribbons, manufactured through advanced processes. As data usage surges, these cables underpin robust infrastructure to meet today’s digital demands.

Optimizing High-Speed Internet Cables Production

Efficient production of high-speed internet cables is essential for today’s networks. The quality of FTTH cabling systems determines reliable connections. Advanced manufacturing aims to improve performance while upholding high standards.

Cabling Systems for FTTH Applications

FTTH cabling systems feature designs that improve signal transmission and cable longevity. They employ premium materials and innovative engineering to deliver fast, dependable internet for users.

Quality Assurance in Fiber Pulling Process

The fiber pulling process is critical in cable production, requiring meticulous attention. Quality checks prevent damage and preserve signal integrity. Integrated monitoring systems guarantee cable reliability and facilitate seamless installation.

Meeting Industry Standards for Optical Fiber Drawing

Adhering to industry standards in optical fiber drawing is crucial for manufacturers. It secures production safety and cable reliability. Enhancing techniques and materials helps comply with these standards, yielding superior cabling systems.

The Bottom Line

The evolution of FTTH cable production lines has transformed telecommunications, enabling manufacturers to produce high-quality, reliable cables for modern internet demands. As technology advances, adopting advanced manufacturing solutions is paramount to improve production efficiency while upholding top standards.

With the rising need for strong infrastructure, companies must embrace innovative methods in their FTTH cable production. These advanced approaches enhance cable reliability and promote sustainable manufacturing in the fiber optic sector.

To stay ahead in the fiber optic cable industry, embracing these advanced solutions is imperative. The future of cable production hinges on such innovations, ensuring telecommunications infrastructure can meet the growing global internet demands.